Language

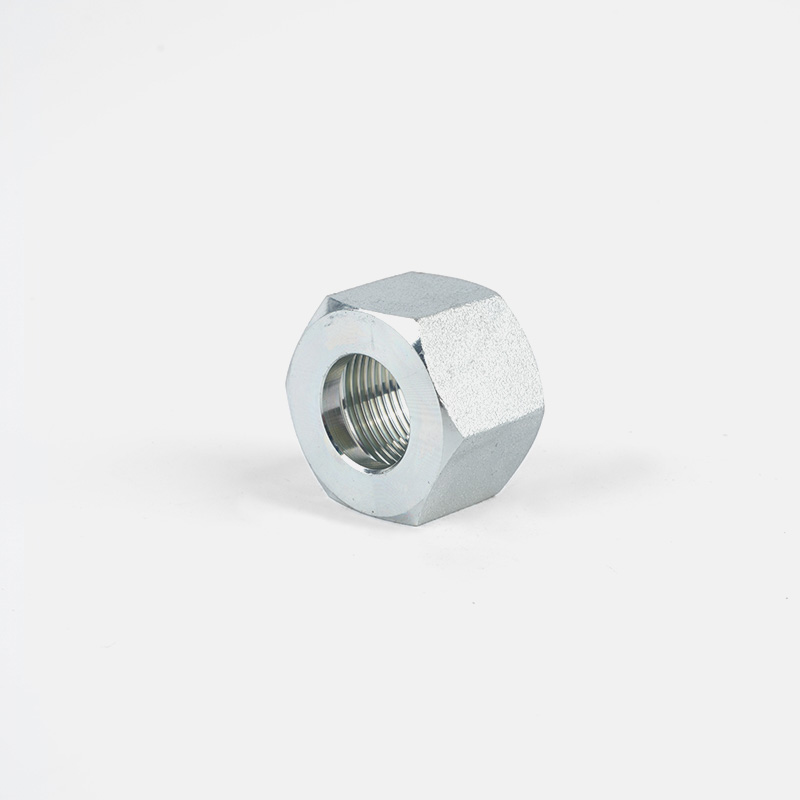

ENGHow Hydraulic Ferrules Improve the Durability of Hydraulic Hoses

2025.08.04

2025.08.04

industy news

industy news

1. Enhanced Leak Prevention

Fluid leakage is one of the most common problems in hydraulic systems, which not only leads to performance degradation, but also brings environmental pollution and safety hazards. A key function of hydraulic flanges is to prevent fluid leakage. By pressing the flange tightly between the hose and the connector, the flange ensures that the hydraulic hose is firmly connected to the hydraulic system. This tight connection prevents the hose from loosening due to pressure changes or temperature fluctuations, effectively avoiding fluid leakage.

How it works:

The flange is designed to wrap evenly around the outside of the hose and form a strong compression seal between the hose and the hydraulic connector. Whether the hydraulic system faces high pressure environments or temperature fluctuations, the hydraulic flange is able to maintain this tight seal to prevent oil leakage.

2. Improved Pressure Handling

Hydraulic systems often need to handle high-pressure fluids. Without proper support, hydraulic hoses may break or burst due to being unable to withstand high pressure. Hydraulic flanges help hoses bear the pressure load more evenly by pressing the hose firmly. The sealing and firmness of the flange ensure that the hose is not prone to leaking or bursting in high-pressure environments.

How it works:

Hydraulic flanges ensure that the pressure of the liquid in the hose is evenly distributed between the hose and the connector. The strength and adaptability of the flanges allow the hose to withstand higher working pressures and reduce the risk of hose rupture.

3. Protection from Abrasive Wear

Hydraulic hoses are often exposed to harsh working environments and may encounter friction from rough surfaces, sharp objects, or other equipment. This physical contact can cause wear on the hose surface and affect the function of the hose. Hydraulic flanges can act as a barrier to protect the hose from this wear.

How it works:

The outside of the flange is usually made of corrosion-resistant and wear-resistant materials, such as stainless steel. They can effectively prevent the hose from direct contact with the external environment and reduce friction on the hose surface, thereby extending the service life of the hose. The design of the flange can also prevent the hose from unnecessary friction and collision with other components.

4. Prevention of Hose Deformation

Hydraulic hoses may be affected by pressure fluctuations, temperature changes, or physical pressure during long-term use, causing the shape of the hose to change, or even flatten or deform. Hydraulic flanges help maintain the original shape of the hose by compressing it to prevent the hose from deforming due to pressure or external forces.

How it works:

When the hydraulic system is under high pressure, the flange will maintain the structural stability of the hose by uniform external force. The strength of the flange can effectively prevent the hose from deforming, thereby maintaining the overall stability of the hydraulic system. The hose is no longer prone to bending, deforming or clogging, which helps ensure the normal operation of the system.

5. Reduction in Vibration Damage

Hydraulic systems, such as those in heavy machinery or mobile equipment, are often subject to vibration. Long-term vibration will cause fatigue in hydraulic hoses, which may eventually cause cracks or ruptures in the hoses. Hydraulic flanges can effectively reduce the impact of these vibrations on the hoses.

How it works:

Flanges prevent hoses from moving during vibration by firmly fixing them to the hydraulic connector. By limiting the relative movement of the hose, the flange reduces friction and wear between the hose and other components, reducing damage caused by vibration. This fixation helps to improve the durability of the hose, especially in high vibration environments.

6. Extended Service Life

A longer service life for hydraulic hoses means less frequent replacement and lower maintenance costs. By properly selecting and installing hydraulic flanges, the chances of hose failure can be significantly reduced. This durability improves the overall efficiency of the hydraulic system, which in turn leads to cost savings.

How it works:

Hydraulic flanges reduce hose damage caused by wear, leakage or pressure fluctuations by optimizing the connection method of the hose. This efficient protection not only extends the service life of the hose, but also reduces equipment downtime and repair costs. Good flange installation helps to extend the overall service life of the hydraulic system and reduce long-term maintenance costs.

7. Compatibility with Multiple Hose Types

Hydraulic flanges are suitable for multiple hose types, including rubber hoses, thermoplastic hoses, and wire braided hoses. This compatibility allows the flanges to be used in different types of hydraulic systems, ensuring system flexibility and versatility.

How it works:

Hydraulic flanges are designed with the needs of different hoses in mind, so they are highly adaptable when selected and installed. Users can choose the right hose type and flange according to specific application requirements to ensure stable and reliable hose connection methods. For example, a wire braided hose may require a stronger flange material to cope with higher pressures, while a thermoplastic hose may require a lighter flange.

8. Corrosion Resistance

Hydraulic systems often operate in harsh environments, exposed to moisture, chemicals, and high temperatures. These environmental factors may cause corrosion to flanges and hoses, reducing their performance and service life. Many high-quality hydraulic flanges are made of corrosion-resistant materials such as stainless steel, which can effectively prevent corrosion.

How it works:

Stainless steel and other alloy materials have excellent corrosion resistance and can maintain stability for a long time in humid or chemical environments. This anti-corrosion property effectively extends the service life of flanges and hoses in working environments with high humidity or frequent contact with chemicals. Corrosion-resistant hydraulic flanges ensure long-term stable operation of hydraulic systems.