Language

ENGImproving connection efficiency: the latest hydraulic quick connector technology trends

2025.07.28

2025.07.28

industy news

industy news

1. Introduction

In modern hydraulic systems, quick couplings have become key components. They can quickly connect and disconnect hydraulic lines and are widely used in agricultural machinery, construction equipment, industrial automation, oil extraction and other fields. With the diversification of application scenarios and the continuous pursuit of work efficiency and safety, the technology of hydraulic quick couplings is also constantly improving.

2. Automatic locking and anti-misoperation design

Traditional hydraulic couplings rely on manual plugging and unplugging, which is prone to leakage or system damage due to improper operation. The new generation of hydraulic quick couplings introduces an automatic locking device, which automatically locks when inserted and requires specific actions when unplugged to effectively prevent accidental detachment.

Many high-end products also integrate color identification, anti-misoperation connection grooves and other designs to ensure that different pipelines will not be misplugged. For example: blue indicates low-pressure circuits and red indicates high-pressure outputs, which helps front-line operators quickly identify.

This type of design is particularly suitable for high-risk, high-frequency operating environments such as construction sites, forestry equipment or military equipment.

3. Breakthrough in leakage-free technology

One of the core challenges of hydraulic systems is leakage. To solve this problem, many manufacturers have adopted dry-break technology. This type of connector will hardly leave any residual hydraulic oil spilling when disconnected**, which can minimize environmental pollution and is particularly suitable for scenarios with high cleaning requirements (such as food processing and medical equipment).

The introduction of new sealing materials (such as Viton® fluororubber, polytetrafluoroethylene PTFE) and multi-layer sealing structures has also greatly improved the stability of connectors under high pressure, high temperature or corrosive media.

These technologies significantly reduce maintenance frequency and downtime, and improve the overall work efficiency and life of the system.

4. Modularization and standardization trend

As global equipment manufacturers increase their demand for maintenance convenience and spare parts versatility, hydraulic quick connectors are moving towards modularization and standardization.

Many connector products have been unified according to international standards (such as ISO 7241-A/B, ISO 16028) to ensure cross-brand and cross-equipment compatibility, greatly facilitating global operation and maintenance.

At the same time, the modular design allows users to freely combine according to different needs, such as:

Replaceable connector body/insert assembly

Matching dust cap, protective ring, extended threaded interface, etc.

This type of structure greatly reduces inventory pressure and is more suitable for centralized management and rapid replacement of large-scale equipment groups.

5. Application of new materials

Traditional quick connectors are mostly made of carbon steel. Although they are strong, they are heavy and have poor corrosion resistance. Today, the introduction of new materials has brought lighter and more durable solutions to hydraulic systems:

Stainless steel (such as 316L): suitable for highly corrosive environments such as oceans and chemicals

High-strength aluminum alloy: lighter weight, easy to use in mobile equipment

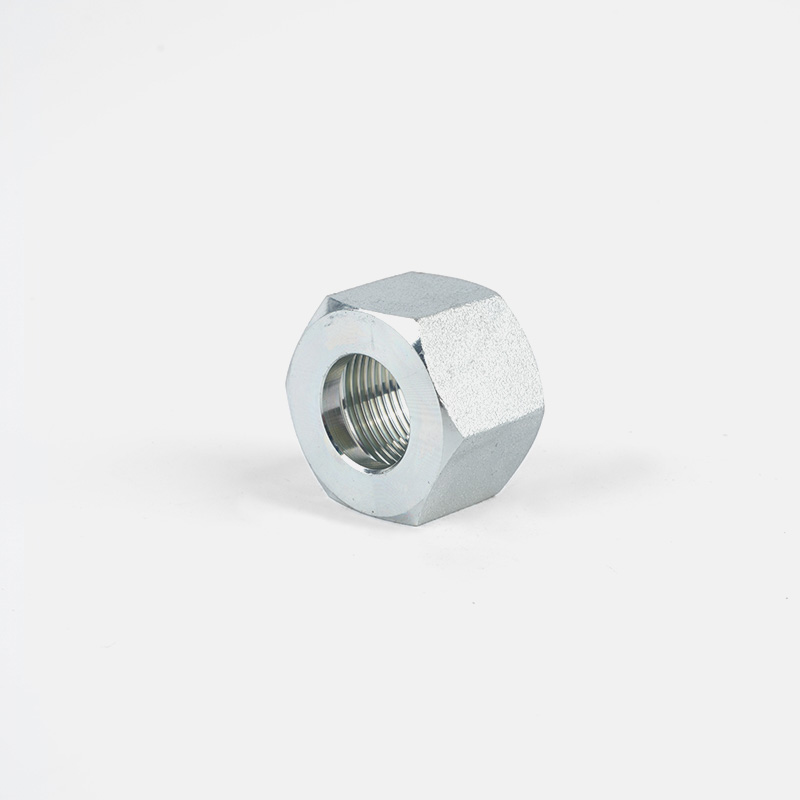

Brass, galvanized alloy: suitable for moderately corrosive environments, high cost performance

Some manufacturers are also developing composite materials or ceramic seals to further extend service life and reduce the overall system burden. The lightweight trend not only improves the portability of equipment, but also reduces operating fatigue and energy consumption.

6. Intelligence and sensor integration

Hydraulic quick connectors are gradually entering the "intelligent" era. Some high-end models begin to integrate:

Pressure sensor: real-time monitoring of pipeline pressure changes

Temperature sensor: warning of overheating to prevent damage to seals

Connection status identification chip (RFID/NFC): realize remote management and fault tracking of the Internet of Things

For example, in industrial robots and automated production lines, once the system detects that the connector is not fully locked, the system alarm can be used to automatically shut down to prevent accidents.

This active safety mechanism not only improves reliability, but also accelerates the integration of hydraulic equipment with Industry 4.0.

7. Green manufacturing and sustainable development

Under the current trend of sustainable development, the manufacturing and design of hydraulic quick connectors are also transforming:

Recyclable materials: environmentally friendly metals or detachable structures are used for easy recycling and reuse

Low-carbon manufacturing process: laser welding and CNC precision machining reduce energy loss

Leakage reduction design: reduce the consumption of hydraulic oil and the risk of pollution to soil and water bodies

More and more equipment manufacturers and end users have included "green connector solutions" in procurement standards as part of corporate social responsibility (CSR).