Language

ENGThe Ultimate Guide to Metric Hose Fittings: Types, Sizes, and Applications

2025.09.15

2025.09.15

industy news

industy news

What Are Metric Hose Fittings?

Metric hose fittings are connectors designed to securely attach hoses to pipes, valves, and other equipment in fluid and gas systems. These fittings are measured using the metric system, meaning their dimensions are based on millimeters (mm), rather than inches. This measurement standard is essential in industries and regions that follow the metric system, like Europe and Asia, ensuring compatibility and precise fitting. Metric hose fittings offer reliable, leak-free connections in hydraulic, pneumatic, and fluid handling systems, making them a critical component in a wide range of industrial applications.

Types of Metric Hose Fittings

Straight Fittings

Straight metric hose fittings are used when a hose needs to connect two parts in a straight line. These fittings have a simple, cylindrical shape and are ideal for situations where the fluid path does not require any direction change. Straight fittings are versatile and can be used in applications where space is not restricted, offering a smooth and unobstructed flow path for the fluid or gas.

Elbow Fittings

Elbow fittings are used when a hose needs to change direction, typically at a 45° or 90° angle. They are crucial for systems where space is limited or when the hose needs to navigate around obstacles. These fittings allow for the redirection of fluid flow without the need to alter the entire system setup. Commonly, elbow fittings are used in tight spaces, like engines or compact machinery, where routing hoses straight is not feasible.

Tee Fittings

Tee fittings are used to split a flow of fluid or gas into two directions. These fittings are shaped like the letter “T” and can come in different configurations, such as equal tees (for uniform flow) or reducing tees (for different sizes of pipes). Tee fittings are useful in systems where one main fluid path needs to be divided into multiple branches, such as in plumbing or cooling systems.

Union Fittings

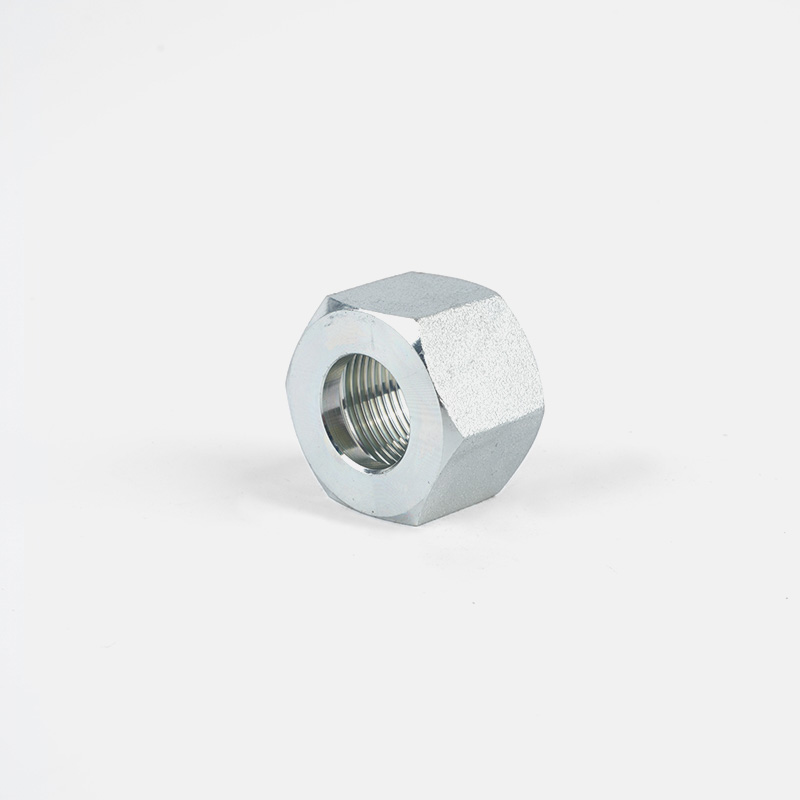

Union fittings allow for easy disassembly and reassembly of hoses without the need to remove the entire fitting from the system. These fittings consist of three parts: two identical female halves and a male section that connects them. Unions are ideal for systems where maintenance is frequent, as they enable quick removal of components without disrupting the entire setup. They are often used in water or chemical processing systems where part replacement is a regular task.

Adapters and Reducers

Adapters and reducers are used when transitioning between different hose sizes, either to connect larger hoses to smaller pipes or vice versa. Metric adapters are essential for ensuring compatibility between various components that use different fitting sizes. Reducers, on the other hand, are used to reduce the size of the fitting to match a smaller pipe or hose diameter. These fittings play a significant role in fluid systems requiring size adjustments to optimize performance and avoid unnecessary restrictions in flow.

Understanding Metric Sizes and Thread Standards

Metric hose fittings are typically available in a wide range of sizes, which are denoted in millimeters. Understanding how to read these sizes and the associated thread standards is crucial to ensure proper fitting and system efficiency. Here’s a breakdown of how to interpret the different metrics used for hose fittings:

| Thread Type | Common Applications | Thread Pitch | Standard |

|---|---|---|---|

| BSP (British Standard Pipe) | Europe and regions using the metric system | 1.5mm - 2.5mm | ISO 7-1 |

| DIN 2353 (EO Fittings) | Hydraulic and pneumatic systems | 1.0mm | DIN 2353 |

| Metric NPT | Applications requiring National Pipe Thread (NPT) compatibility | 1.5mm - 3.0mm | ISO 228-1 |

Nominal Diameter: Typically the size of the hose or the internal diameter of the fitting, measured in millimeters (e.g., 10mm, 12mm, 16mm).

Thread Type: Common thread types include BSP, DIN, and NPT, each with its own specifications for thread pitch and compatibility across different regions and standards. The right thread type ensures a secure, leak-proof connection in your system.

Choosing the Right Metric Hose Fitting for Your System

Choosing the right fitting is essential for the safety and performance of your system. Here are some factors to consider:

Pressure Rating

Ensure the fitting is rated for the pressure your system will be under. Overestimating or underestimating the pressure rating can lead to leaks or system failure. Most fittings will come with manufacturer-provided pressure ratings that correspond to the material and construction of the fitting.

Material Compatibility

Matching the fitting material (e.g., stainless steel, brass, or aluminum) with the type of fluid or gas being transported is essential to prevent corrosion, wear, or contamination. For example, stainless steel is highly resistant to corrosion and is often used in systems handling harsh chemicals, while brass is commonly used in water or fuel systems.

Temperature Range

Make sure the fitting can withstand the temperature extremes your system may experience. High or low temperatures can cause materials to expand, contract, or degrade, compromising the seal integrity. Fittings designed for extreme temperature ranges should be specified for such environments.

Size and Flow Requirements

Always check the flow requirements of your system to ensure the fitting size will deliver optimal performance without causing unnecessary restrictions. Using a fitting that’s too small can reduce flow and pressure, while an oversized fitting may result in leaks.

Applications of Metric Hose Fittings

Automotive Industry

Metric hose fittings are extensively used in automotive systems for fuel, hydraulic, and cooling lines. Their precise measurements ensure a secure and leak-proof fit, which is essential for vehicle performance and safety. These fittings are especially crucial in the manufacturing of modern vehicles, where efficient and reliable fluid handling is required for optimal engine performance.

Hydraulic Systems

In hydraulic machinery, metric hose fittings are essential to connect hoses to pumps, cylinders, and valves. These fittings are often made of high-strength materials to withstand the high-pressure environments common in hydraulic systems. They ensure leak-free, safe, and efficient fluid transfer, making them an integral part of equipment used in construction, manufacturing, and more.

Aerospace

In aerospace systems, reliability and precision are critical. Metric hose fittings are used to connect critical fluid lines, ensuring that they can handle extreme pressures, temperatures, and environmental conditions. In aircraft and spacecraft, even small leaks can cause catastrophic failure, so these fittings are designed with the highest standards of performance and durability in mind.

Agriculture and Construction

Heavy-duty machinery, such as tractors and excavators, rely on metric hose fittings to manage fluid systems. These systems must operate reliably in tough conditions, and choosing the right fitting can prevent downtime and costly repairs. Agricultural irrigation systems also make extensive use of these fittings to ensure water flows efficiently and consistently.

Maintenance and Troubleshooting

While metric hose fittings are durable, regular maintenance is crucial to ensure their performance over time. Here are some tips for keeping your fittings in top shape:

Regular Inspections

Inspect fittings regularly for signs of wear, corrosion, or damage. Look for any signs of leakage or loose connections that could compromise the integrity of your system. Promptly replace damaged fittings to prevent larger system failures.

Proper Tightening

Ensure that fittings are properly tightened but avoid over-tightening, which can lead to thread damage or material deformation. Tighten fittings using the recommended torque specifications provided by the manufacturer.

Clean the Threads

Regularly clean the threads and fittings to prevent dirt or debris from causing leaks or obstructing fluid flow. A clean connection is essential for a leak-free system, and any contaminants should be removed during maintenance.

Use Correct Sealing Materials

To ensure leak-free connections, use the correct sealing materials, such as O-rings, PTFE tape, or sealing washers. These materials help form an effective seal, preventing fluid or gas from escaping through the threads.