Language

ENGWhat Are Hydraulic Ferrules and How Do They Work in Fluid Systems?

2025.11.17

2025.11.17

industy news

industy news

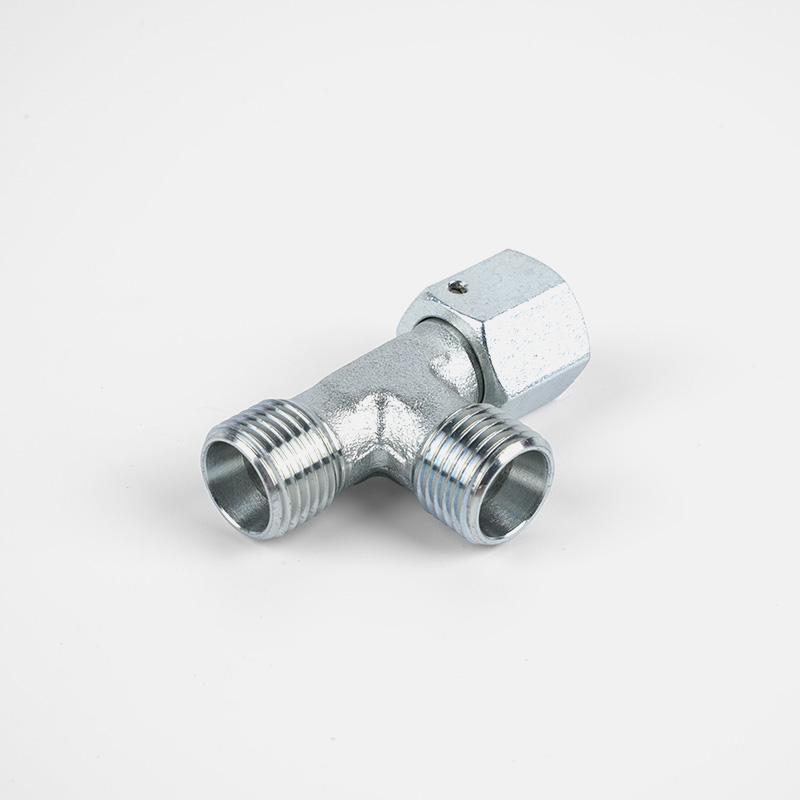

Hydraulic ferrules are crucial components in hydraulic systems, ensuring the proper connection between hoses and fittings to maintain a leak-free, high-pressure fluid flow. They play a significant role in various industries, from automotive to industrial machinery.

What is a Hydraulic Ferrule?

A hydraulic ferrule is a type of fitting used to secure hydraulic hoses to their respective connectors. It is typically a metal or synthetic sleeve placed around the hose and compressed using a crimping tool. The ferrule’s purpose is to ensure a tight, leak-proof connection between the hose and the fitting, which is critical for maintaining the integrity of the hydraulic system under pressure.

Ferrules are usually manufactured from high-strength materials such as stainless steel, brass, or carbon steel. These materials offer resistance to wear, corrosion, and extreme temperatures, ensuring that the ferrules can handle the demanding conditions of high-pressure fluid systems.

How Do Hydraulic Ferrules Work?

Hydraulic ferrules work by securing the hydraulic hose to the fitting, forming a strong and leak-resistant joint. This process is vital to prevent fluid loss and ensure the system can maintain the required pressure levels. Let’s break down the steps involved in how hydraulic ferrules function:

Hose Connection

When setting up a hydraulic system, the first step is to connect the hose to the hydraulic fitting. The ferrule is placed over the hose, ensuring that the connection is properly aligned with the fitting. The ferrule, acting as a protective sleeve, ensures that the hose stays securely in place.

Crimping Process

Once the ferrule is in position, the next step is crimping. Crimping is a process in which the ferrule is compressed onto the hose and fitting using a specialized crimping tool. The crimping tool applies significant pressure, forcing the ferrule to tightly grip the hose and fitting. This ensures that there is no possibility of fluid leakage at the connection point.

The crimped ferrule effectively creates a seal around the hose, fitting, and ferrule itself. This seal prevents fluid from escaping under high-pressure conditions, which is essential for maintaining system pressure and preventing operational inefficiencies.

Pressure Handling

One of the primary functions of hydraulic ferrules is to withstand high fluid pressures. When the ferrule is properly crimped, it helps distribute the pressure uniformly across the connection, reducing the chance of hose failure or leakage. Hydraulic ferrules are designed to handle the immense pressure generated in many hydraulic systems, especially in industries such as construction, manufacturing, and aerospace.

Leak Prevention

The most crucial aspect of hydraulic ferrules is their ability to prevent leaks. In hydraulic systems, even the smallest leak can lead to significant operational disruptions, fluid loss, or system failures. The crimped ferrule ensures that the connection is tightly sealed, preventing any fluid from escaping. This is especially critical in high-pressure systems, where leaks can result in equipment malfunction, safety hazards, and costly downtime.

Why Are Hydraulic Ferrules Important?

Hydraulic ferrules may seem like small components, but they play an essential role in the performance, reliability, and safety of hydraulic systems. Here are some of the key reasons why they are important:

Leak Prevention

Leakage in hydraulic systems can lead to performance inefficiencies, damage to equipment, and unsafe working conditions. Hydraulic ferrules provide a tight seal between hoses and fittings, preventing leaks and ensuring that the system operates efficiently. Without properly installed ferrules, the risk of leaks increases, which can lead to costly repairs and downtime.

Pressure Resistance

Hydraulic systems often operate under extremely high pressures. Hydraulic ferrules are designed to withstand these pressures and ensure that the system remains intact even under demanding conditions. By properly crimping the ferrule, you ensure that the system can handle the pressure without compromising the integrity of the hose or fittings.

System Longevity

A well-maintained hydraulic system will last longer and require fewer repairs. Hydraulic ferrules contribute to the system’s longevity by preventing leaks, reducing wear, and maintaining the integrity of the entire system. Proper installation and maintenance of ferrules can help extend the lifespan of hydraulic systems, saving both time and money in the long run.

Safety

In industries such as oil and gas, aerospace, and automotive, safety is a top priority. Hydraulic ferrules ensure that fluid systems remain sealed and intact, preventing accidents or failures that could lead to safety hazards. A failure in a hydraulic system, especially in high-pressure environments, could result in catastrophic consequences, so using ferrules is crucial for maintaining safe operations.

Types of Hydraulic Ferrules

There are several types of hydraulic ferrules, each suited for different applications and pressures. Below are some of the most common types:

-

Crimp Ferrules: These are the most commonly used ferrules. They are applied by crimping the ferrule onto the hose and fitting using a hydraulic crimping tool. Crimp ferrules provide a secure, leak-resistant connection for most hydraulic systems.

-

Push-On Ferrules: These ferrules are designed for applications that do not require high-pressure connections. The ferrule simply “pushes on” to the hose and fitting, without the need for crimping. They are used for lower-pressure systems or temporary setups.

-

Reusable Ferrules: Some ferrules are designed to be reused. These ferrules can be taken off the hose, cleaned, and reinstalled if the hose needs to be replaced or serviced. Reusable ferrules are cost-effective and environmentally friendly.

Common Applications of Hydraulic Ferrules

Hydraulic ferrules are used in a wide variety of industries where fluid transmission is essential. Some of the most common applications include:

Industrial Machinery

In industrial settings, hydraulic ferrules are used to secure hoses and fittings on equipment such as presses, forklifts, and conveyor systems. These machines often operate under high pressure, making the use of reliable ferrules essential to ensure safe and efficient operation.

Automotive and Transportation

Hydraulic ferrules are used in a variety of automotive applications, including brake lines, power steering systems, and hydraulic lifts. They help maintain the performance and safety of these systems, which are critical for the proper functioning of vehicles and heavy machinery.

Construction Equipment

Construction machines, such as cranes, bulldozers, and excavators, rely heavily on hydraulic systems to operate. Hydraulic ferrules are used to connect hoses to various components, ensuring a secure and leak-free connection even in the harshest environments.

Oil and Gas Industry

In the oil and gas sector, hydraulic ferrules are used in offshore platforms, pipelines, and rigs to maintain a secure and pressure-resistant connection between hoses and fittings. These systems are exposed to extreme pressures and harsh conditions, making hydraulic ferrules a critical component for operational safety and reliability.

How to Install Hydraulic Ferrules

Installing hydraulic ferrules requires attention to detail to ensure the connection is secure and leak-free. Here’s a step-by-step guide to the installation process:

-

Select the Correct Ferrule: Ensure that you choose the right ferrule for your hose and fitting, considering factors such as pressure rating, material compatibility, and environmental conditions.

-

Prepare the Hose and Fitting: Cut the hose to the required length and ensure that the end is clean and free of debris. Insert the fitting into the hose to prepare for the ferrule.

-

Position the Ferrule: Slide the ferrule over the hose, making sure it is positioned correctly over the fitting and hose end.

-

Crimp the Ferrule: Using a crimping tool, apply the correct amount of pressure to compress the ferrule onto the hose and fitting. The crimp should be uniform and tightly secure the ferrule in place.

-

Inspect the Connection: After crimping, check the connection for leaks and ensure that the hose is securely attached to the fitting. This can be done using a pressure test or visually inspecting the crimped ferrule.