Language

ENGAre All Hydraulic Couplings Interchangeable? A Guide to ISO Standards and Sizes

2026.02.16

2026.02.16

industy news

industy news

In the demanding world of hydraulic machinery, the hydraulic coupling is the critical link that ensures power is transmitted without loss. However, one of the most persistent and dangerous myths in the industry is that all couplings of the same size are interchangeable. For a professional enterprise, assuming that two couplings are compatible simply because they “look similar” can lead to catastrophic system failure, expensive oil spills, and severe safety hazards. Whether you are managing heavy-duty construction equipment or integrating fluid lines with industrial Immersion Water Heaters, understanding the rigorous ISO standards that govern these components is essential for operational reliability.

The Reality of Interchangeability: Why Design Matters

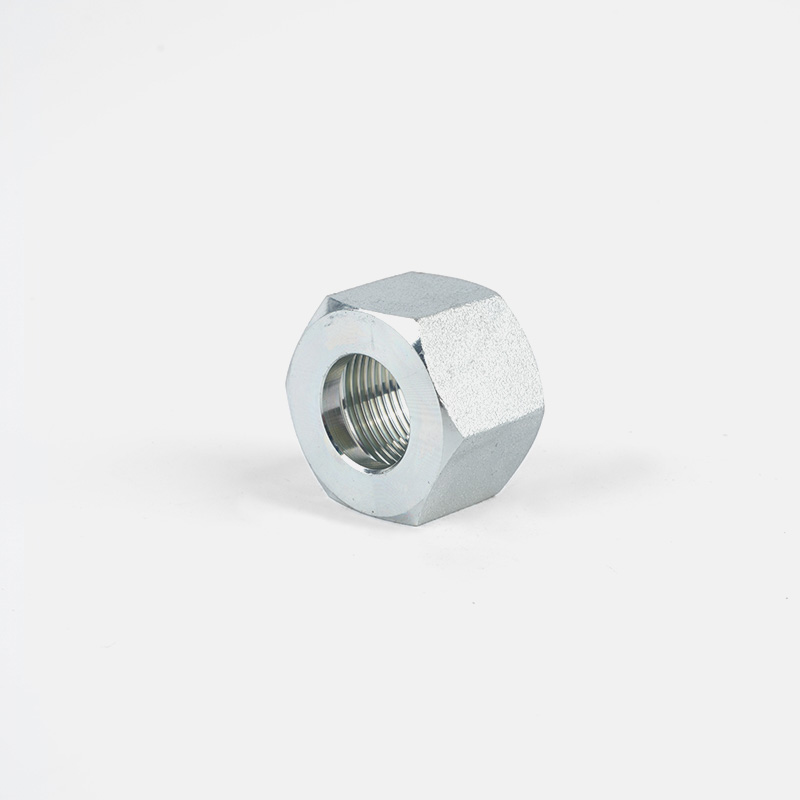

The short answer to the question of universal interchangeability is a definitive no. While the hydraulic industry has made massive strides toward standardization, many proprietary designs still exist. A Hydraulic Quick Disconnect coupling from one manufacturer may physically enter the socket of another, but if the internal valve seating or the locking ball groove is off by even a fraction of a millimeter, the connection is compromised.

The Dangers of “False Connections”

A false connection occurs when the male and female parts lock together but fail to open the internal valves fully. This creates a massive pressure drop, generating excessive heat that can damage sensitive downstream components like Heating Elements or seals. In worse cases, the coupling may “blow out” under full working pressure, leading to a high-velocity oil spray that poses a fire risk and a significant environmental cleanup cost.

How ISO Standards Protect Your System

To mitigate these risks, the International Organization for Standardization established benchmarks like ISO 7241 and ISO 16028. These standards specify the exact dimensions, tolerances, and performance requirements (such as burst pressure and flow rate) for couplings. By sourcing ISO-certified parts, B2B procurement managers can ensure that a male nipple from one certified supplier will safely and efficiently mate with a female socket from another, providing much-needed flexibility in global supply chains.

Decoding the Major Standards: ISO 7241 vs. ISO 16028

When browsing a product catalog for Hydraulic Couplings, you will frequently encounter three major standardized categories. Understanding the difference between them is key to maintaining system integrity.

ISO 7241 Series A and Series B

- ISO 7241-A: This is the primary choice for agricultural and construction machinery. If you are working with tractors or excavators, this is likely what you need. It features a poppet valve design that is reliable and cost-effective.

- ISO 7241-B: Preferred in the chemical and general industrial sectors. It offers a different profile and is often manufactured in materials like Stainless Steel or Brass to handle corrosive fluids or specialized industrial cooling lines connected to Electrical Water Heater Stems.

ISO 16028 - The Flat Face Revolution

The ISO 16028 standard governs Flat Face Couplings. These were designed specifically to address the “dirty” nature of hydraulic connections. The flush mating surfaces mean that no air is trapped in the system during connection, and no oil leaks out during disconnection. In 2026, environmental regulations are stricter than ever, making “No-Spill” flat face couplings the preferred choice for eco-conscious construction sites and clean-room manufacturing environments.

Size Identification and Nominal Flow

It is a common mistake to measure the outside diameter of a coupling and assume its size. In the hydraulic world, size refers to the Nominal Diameter (DN), which relates to the flow capacity. A 1/2" nominal coupling might have a physical diameter much larger. Always refer to the ISO size code (e.g., ISO 12.5 for a 1/2" coupling) to ensure you are comparing “apples to apples” when reviewing supplier specifications.

Technical Specifications and Compatibility Matrix

For a manufacturing enterprise like CN-FPDQ, choosing the right coupling requires a balance between pressure ratings and flow efficiency. The following table provides a quick reference for the most common standardized couplings used in industrial fluid power.

Comparison of Standardized Hydraulic Couplings

| Feature | ISO 7241-A (Poppet) | ISO 7241-B (Industrial) | ISO 16028 (Flat Face) |

|---|---|---|---|

| Interchangeability | High (Global Ag/Const) | High (Industrial) | Universal (Non-spill) |

| Max Pressure (1/2") | 250 - 315 Bar | 250 - 300 Bar | 315 - 400 Bar |

| Spillage on Disconnect | Moderate | Moderate | Negligible / Zero |

| Primary Material | Carbon Steel | Steel / Brass / SS | Carbon Steel / SS |

| Fluid Loss (ml) | ~1.5 - 3.0 | ~1.5 - 3.0 | < 0.02 |

| Best Application | Mobile Machinery | Chemical / Plants | Construction / Green Sites |

Integrating Hydraulic and Electrical Systems in Industrial Settings

In advanced manufacturing, hydraulic systems and electrical systems often work side-by-side. For instance, an industrial machine might use a hydraulic actuator for movement while utilizing a Heating Element to maintain fluid temperature.

Thermal Efficiency and Flow Optimization

Using the correct, interchangeable Hydraulic Couplings ensures that the fluid flow is not restricted. Flow restriction causes “turbulence,” which leads to an increase in hydraulic fluid temperature. If the fluid exceeds its optimal operating temperature, it can put an unnecessary load on the system’s cooling unit and potentially conflict with the calibrated output of your Immersion Water Heater. Standardized couplings are flow-tested to ensure they meet the specific pressure-drop curves required for high-efficiency thermal management.

Safety and Workplace Organization

Workplace safety involves more than just secure connections; it involves cable and hose management. Ensuring that your Power Cords and Extension Cords are kept away from hydraulic lines is crucial. A leak from a non-interchangeable or poorly fitted coupling can spray flammable hydraulic oil onto high-voltage Power Strips, creating a severe fire hazard. By using ISO-compliant couplings, you significantly reduce the risk of spray-leaks, keeping your electrical and hydraulic systems safely separated.

FAQ: Frequently Asked Questions

Q: Can I connect an ISO 7241-A male to an ISO 7241-B female?

A: No. Despite having the same name (ISO 7241), the “A” and “B” series have completely different physical profiles and will not mate.

Q: How do I identify a “Flat Face” coupling?

A: A Flat Face coupling (ISO 16028) has a smooth, flat mating surface that looks like a button. It is designed to be wiped clean easily before connection.

Q: Are thread types (NPT, BSPP, Metric) part of the ISO coupling standard?

A: No. The ISO standard governs the “mating” end of the coupling. The “back end” (the port) can have various thread types like NPT or BSPP. You must ensure both the coupling type and the thread type match your hose.

Q: Why is “Connect Under Pressure” a special feature?

A: Standard couplings cannot be connected if there is residual pressure in the line. Some specialized interchangeable versions feature a “Pressure Eliminator” valve that allows for manual connection even when the system is pressurized.

References & Further Reading

- ISO 7241:2026 - Hydraulic fluid power — Quick-action couplings — Dimensions and requirements.

- National Fluid Power Association (NFPA) - Fluid Power Standards for Industrial Machinery.

- International Journal of Fluid Power - Analysis of Pressure Drop in Standardized Hydraulic Connectors.