Language

ENGWhat Are Metric Hose Fittings and How Do They Differ from Imperial Fittings?

2026.01.19

2026.01.19

industy news

industy news

What Are Metric Hose Fittings?

Metric hose fittings are specialized connectors used to join hoses, pipes, and tubes in hydraulic and fluid transmission systems that follow the metric measurement system. Unlike inch-based fittings, all critical dimensions—such as thread diameter, pitch, and sealing surfaces—are defined in millimeters (mm). These fittings are widely used in machinery and equipment manufactured for global markets, particularly in Europe and Asia.

Metric hose fittings are commonly produced according to DIN, ISO, and EN standards, which ensures consistency, interchangeability, and safety across different manufacturers. Typical applications include construction machinery, agricultural equipment, industrial hydraulics, automotive systems, and factory automation. Because many OEM machines are designed around these standards, metric hose fittings have become the default choice for international equipment.

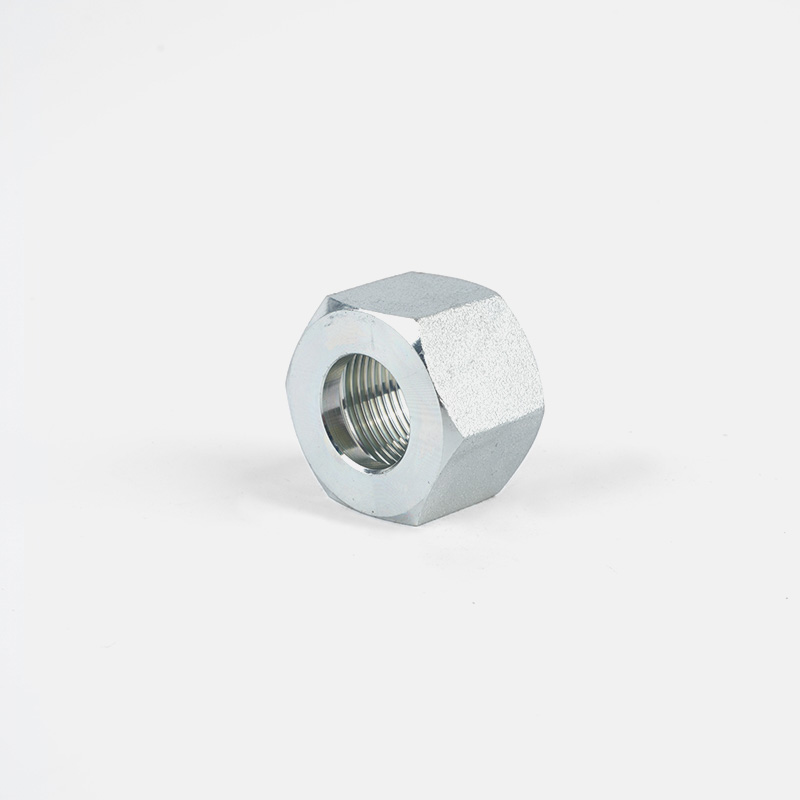

A key feature of metric hose fittings is their straight-thread design, which does not rely on thread deformation to create a seal. Instead, sealing is achieved through a metal-to-metal cone, an O-ring, or a flat sealing surface. This design significantly reduces the risk of leaks, especially in high-pressure or high-vibration environments.

Common metric hose fitting types include Metric 24° Cone fittings (with or without O-rings), Metric Flat Face fittings, and DIN 2353 Light and Heavy series fittings. Each type is engineered for specific pressure ratings and working conditions. Because of their precision and reliability, metric hose fittings are increasingly preferred in modern hydraulic system design.

What Are Imperial Hose Fittings?

Imperial hose fittings are connectors manufactured using the inch-based measurement system, which is traditionally used in the United States and some other regions. These fittings measure thread size in inches and define thread pitch by threads per inch (TPI) rather than millimeters. Imperial hose fittings are governed by standards such as SAE, JIC, NPT, and BSP.

Imperial fittings have a long history in hydraulic and industrial systems, especially in North American markets. Many legacy machines, agricultural equipment, oil and gas installations, and mobile hydraulic systems still rely heavily on imperial standards. As a result, imperial hose fittings remain widely available and commonly specified in these industries.

One notable characteristic of imperial fittings is the variety of sealing methods they use. For example, NPT fittings seal through thread taper and interference, while JIC fittings use a 37° flare for metal-to-metal sealing. BSP fittings, although inch-based, are widely used internationally and may seal with an O-ring or washer.

Because imperial hose fittings were developed earlier than metric standards, they sometimes lack the level of global uniformity found in metric systems. This can make sourcing and compatibility more challenging in international supply chains. Nevertheless, imperial fittings remain reliable and effective when correctly specified and installed within their intended systems.

How Do Metric and Imperial Hose Fittings Differ in Measurement and Standards?

The most fundamental difference between metric and imperial hose fittings lies in their measurement systems and governing standards. Metric fittings use millimeters to define all dimensions, while imperial fittings rely on inches and threads per inch. This difference affects not only sizing but also how fittings are identified, specified, and installed.

Metric hose fittings are typically standardized under DIN (German Institute for Standardization) or ISO (International Organization for Standardization) regulations. These standards emphasize global compatibility, which is why metric fittings are widely used in internationally traded machinery. Imperial fittings, on the other hand, are governed by regional standards such as SAE or ANSI.

Even when two fittings appear visually similar, the dimensional differences can be subtle but critical. A metric thread may have a slightly different pitch or diameter compared to its imperial counterpart, making them incompatible despite seeming to fit together initially. Improper mixing can result in cross-threading, sealing failure, or catastrophic system leaks.

| Feature | Metric Hose Fittings | Imperial Hose Fittings |

|---|---|---|

| Measurement Unit | Millimeters (mm) | Inches |

| Thread Pitch | Distance between threads (mm) | Threads per inch (TPI) |

| Main Standards | DIN, ISO, EN | SAE, NPT, JIC, BSP |

Understanding these measurement and standard differences is essential for engineers, buyers, and maintenance teams to avoid costly errors.

How Do Sealing Methods Differ Between Metric and Imperial Fittings?

Sealing method is one of the most critical distinctions between metric and imperial hose fittings. Metric hose fittings are generally designed with advanced sealing mechanisms that separate the sealing function from the threads. This results in more reliable and repeatable connections.

Most metric fittings seal using a 24° cone, often combined with an elastomer O-ring. This design allows the fitting to maintain a tight seal even under pressure fluctuations, vibration, or temperature changes. Because the threads are not responsible for sealing, they experience less wear and damage over time.

Imperial fittings vary more widely in their sealing approaches. NPT fittings rely on tapered threads that deform slightly to create a seal, which can increase the risk of leaks if over-tightened or reused. JIC fittings use a metal-to-metal flare, which provides good sealing but requires precise alignment during installation.

Overall, metric hose fittings are often preferred in modern hydraulic systems because their sealing methods offer greater reliability, easier maintenance, and improved safety, particularly in high-pressure applications.

Which Applications Favor Metric Hose Fittings Over Imperial Ones?

Metric hose fittings are predominantly used in international and export-oriented equipment. European-manufactured machinery almost exclusively relies on metric standards, as do many machines produced in Asia. Industries such as construction, mining, agriculture, and industrial automation commonly specify metric hose fittings for this reason.

Imperial fittings are still widely used in North American domestic equipment, particularly in oil and gas, agriculture, and older hydraulic systems. However, as globalization increases, many manufacturers are transitioning toward metric systems to simplify supply chains and reduce regional variations.

For OEMs and suppliers serving global markets, metric hose fittings offer a clear advantage. They align with international standards, reduce the need for adapters, and improve compatibility across different regions. This is why metric fittings are increasingly considered the future-proof choice in hydraulic system design.

FAQ

Q1: Can metric and imperial hose fittings be mixed?

In most cases, no. Mixing metric and imperial fittings can lead to leaks, thread damage, and system failure unless a proper adapter is used.

Q2: Are metric hose fittings better than imperial ones?

Neither is inherently better; metric fittings are more globally standardized, while imperial fittings remain effective in legacy and regional systems.

Q3: How can I identify whether a fitting is metric or imperial?

Measure the thread diameter and pitch using calipers or a thread gauge. Metric threads are measured in millimeters, imperial in inches and TPI.

Q4: Do metric hose fittings handle high pressure well?

Yes. Metric fittings, especially DIN Heavy Series, are designed for high-pressure hydraulic applications.

References

- ISO 8434 – Metal Tube Connections for Fluid Power and General Use

- DIN 2353 – Compression Fittings for Hydraulic Fluid Power

- SAE J514 – Hydraulic Tube Fittings

- Parker Hannifin, Hydraulic Fitting Standards Guide

- Eaton Hydraulics, Industrial Hose and Fitting Technical Manual