Language

ENGHow to choose the right hydraulic connector to improve system performance

2025.08.18

2025.08.18

industy news

industy news

1. Understand the operating parameters of the hydraulic system.

Hydraulic connectors must withstand the hydraulic system's operating pressure, which typically ranges from tens of bars to thousands of bars. Determine the system's maximum operating pressure and select connectors with a safety factor that can withstand at least 1.5 or even 2 times that pressure to prevent failure due to pressure fluctuations.

The system's flow rate affects the flow velocity within the pipeline. Excessively high flow rates can cause vibration and noise at the connector, accelerating wear. Connector design should consider fluid dynamics to avoid resistance or turbulence.

Temperature is also a critical parameter. Hydraulic oil temperatures can range from -40°C to 150°C under different operating conditions. Connector materials and seals must withstand the system's operating temperature; otherwise, they will harden, age, and fail.

A comprehensive consideration of pressure, flow, and temperature ensures the connector's safety and reliability in actual operating conditions.

2. Select the connector type based on the pipeline and equipment interface.

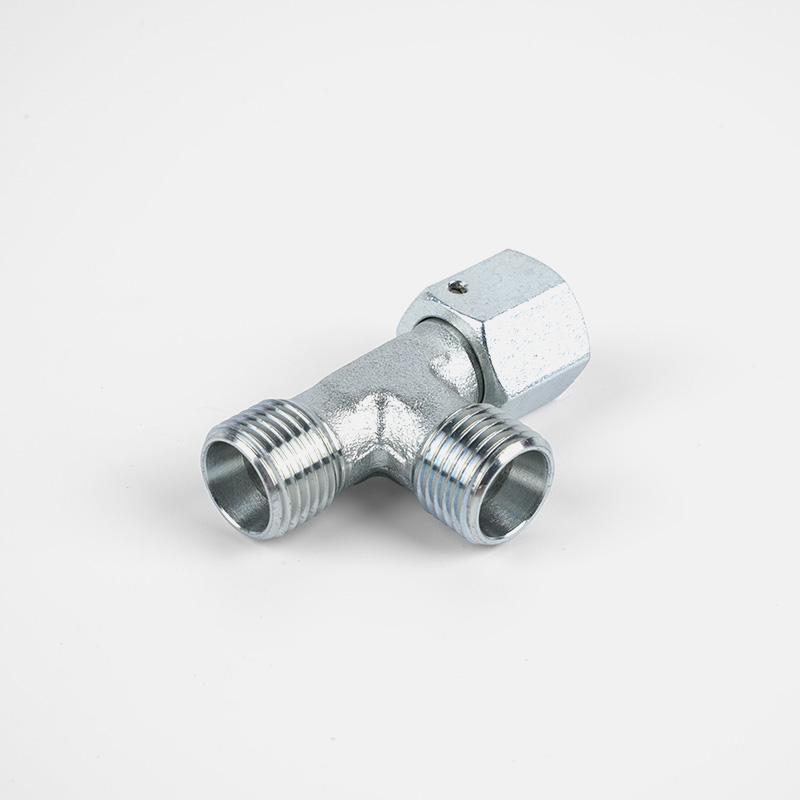

Hydraulic pipelines come in a variety of design styles. Hydraulic connectors come in a variety of styles, including straight-through, 90-degree elbows, 45-degree elbows, and tees, to meet diverse piping layout requirements. The correct fitting shape can effectively reduce piping stress and avoid unnecessary space waste.

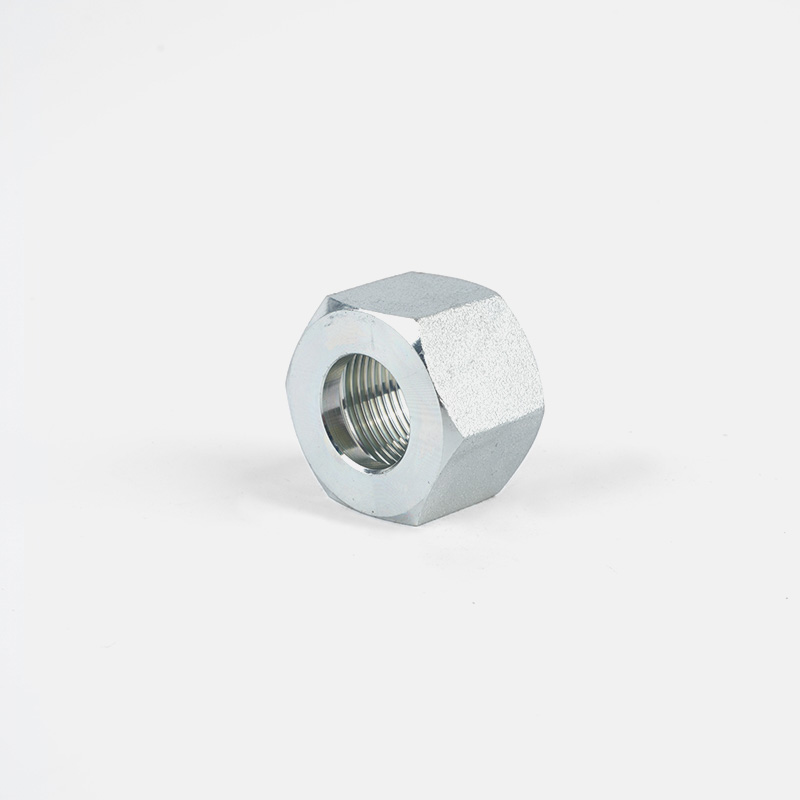

The interface type is equally important. Hydraulic fittings offer a variety of connection methods, including threaded connections (such as NPT, BSP, and SAE), compression fittings, and quick-connects. Different interfaces are suitable for different system designs and maintenance requirements. It is crucial to select matching fittings based on the interface standards of the piping and equipment to ensure a tight, leak-free connection.

The pipe diameter and wall thickness must also match the fitting specifications to avoid installation difficulties or system performance degradation due to dimensional mismatches.

3. Material Selection Affects Durability and Safety

Common materials for hydraulic fittings include carbon steel, stainless steel, and brass.

Carbon steel: High strength and low cost, suitable for general industrial environments and pressure conditions. However, it has poor corrosion resistance and is prone to rust, requiring corrosion protection treatment.

Stainless steel: Offers excellent corrosion resistance and high-temperature resistance, making it suitable for corrosive environments such as chemical, food, and marine applications, as well as high-pressure systems. However, it is more expensive.

Brass: Good machinability and corrosion resistance make it suitable for low-pressure systems and aqueous media, but its strength is not as high as that of carbon steel and stainless steel. Proper material selection can effectively extend the service life of hydraulic connectors, reduce failure frequency, and improve system safety.

4. Focus on sealing performance to enhance system stability.

The sealing performance of a hydraulic system directly impacts the risk of oil leakage and pressure stability. Hydraulic connectors are typically equipped with a variety of seals, with common materials including NBR (nitrile rubber), fluororubber (FKM), and polyurethane (PU).

NBR: Excellent oil resistance, affordable, and suitable for general operating conditions.

Fluororubber: High temperature and chemical resistance, suitable for high-temperature or corrosive media.

Polyurethane: Excellent wear resistance, suitable for dynamic sealing.

When selecting sealing materials, consider the system media type, temperature range, and pressure conditions to ensure stable performance and prevent leakage under the operating environment.

The sealing structure in the connector design (such as O-rings and cone seals) is also crucial to sealing effectiveness. Proper structural design can reduce wear and leakage.

5. Select appropriate manufacturing standards and certifications.

The quality standards of hydraulic connectors directly impact product reliability. Commonly used international standards for hydraulic connectors include ISO (International Organization for Standardization), SAE (Society of Automotive Engineers), and DIN (Deutsche Industrie Norm).

Connectors that meet these standards have strict specifications for dimensions, pressure tolerance, material selection, and testing methods, ensuring stable performance and interchangeability.

When purchasing, try to choose manufacturers with ISO9001 quality management system certification and relevant product certifications (such as CE and RoHS) to maximize product quality and after-sales service.

6. Consider maintenance convenience and replacement costs.

When maintaining a hydraulic system, the ease of assembly and disassembly of hydraulic connectors directly impacts maintenance efficiency. Quick-connect designs allow for rapid, tool-free disassembly, making them suitable for frequent assembly and disassembly, saving maintenance time.

Also, the durability of hydraulic connectors determines replacement frequency. High-quality, corrosion-resistant, and wear-resistant connectors, while slightly more expensive, can reduce repairs and downtime, resulting in greater long-term economic benefits.

Planning the connector layout appropriately, selecting types and locations that facilitate easy maintenance, can also improve overall maintenance efficiency.