Language

ENGWhat Are Metric Hose Fittings and Why Are They Important in Fluid Systems?

2025.12.22

2025.12.22

industy news

industy news

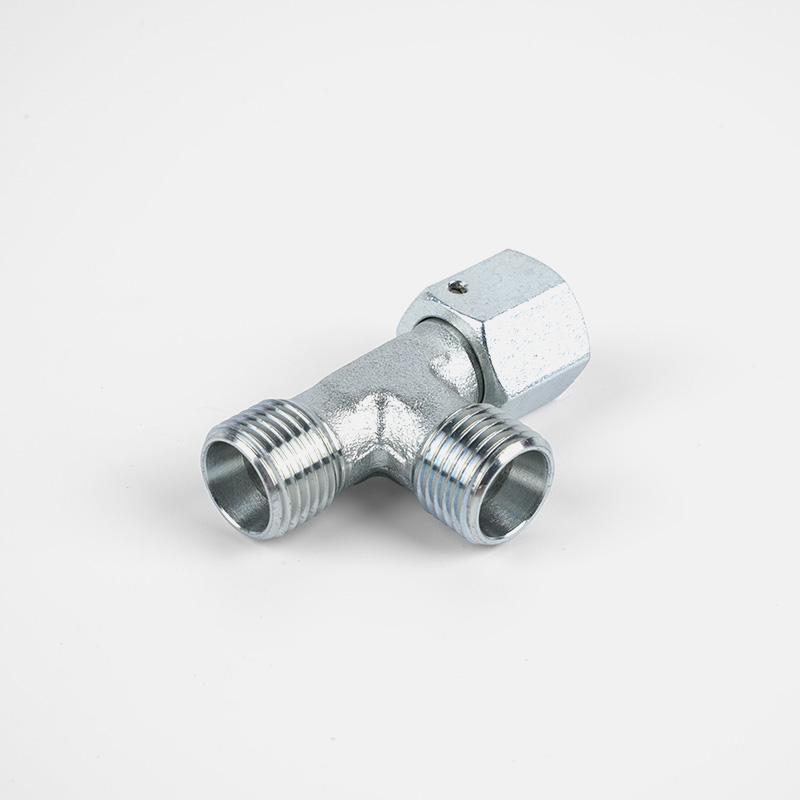

Metric hose fittings are critical components that allow for the secure connection of hoses, pipes, and tubes in fluid systems. These fittings follow the metric system’s standard measurements, unlike the imperial system used in some regions like the United States. In fluid systems, whether for industrial machinery, automotive systems, or hydraulic circuits, these fittings ensure that hoses are firmly attached to equipment and that fluids or gases flow efficiently without leaks.

The use of metric hose fittings has become especially prominent in regions that use the metric system, such as Europe. Their universal standardization allows for consistency in fluid transfer systems across various industries. This ensures compatibility between different manufacturers’ components, eliminating potential issues that arise when parts are not standardized.

What Makes Metric Hose Fittings Different?

Metric hose fittings are primarily differentiated by their size, thread type, and material. The most common sizes are denoted in millimeters, for example, M16 or M22, where the number represents the outer diameter of the fitting in millimeters. These fittings are designed with specific threading systems, such as the ISO 8434-1 standard, which is widely recognized across various industries for ensuring compatibility between hoses and other system components.

Another critical difference between metric and imperial fittings is that metric hose fittings are often more precise, providing a tighter, more secure connection, which is especially important in high-pressure or critical fluid applications. The materials used for manufacturing metric hose fittings also vary, with stainless steel, brass, and aluminum being the most common. These materials are chosen for their resistance to corrosion and durability, making them ideal for use in harsh environments where leaks or corrosion could cause severe problems.

The Importance of Metric Hose Fittings in Fluid Systems

-

Ensuring Leak-Free Connections: One of the most important roles of metric hose fittings is to provide secure, leak-free connections between hoses and other system components. When a hose is attached to a pump, valve, or any other piece of equipment, the fitting ensures that the connection is tight enough to prevent leaks under pressure. This is especially important in high-pressure systems, where even a small leak can lead to fluid loss, safety hazards, or system inefficiency.

-

Standardization: Since metric hose fittings adhere to internationally recognized standards, they offer a level of uniformity that is crucial for maintaining system integrity. With these standardized measurements, manufacturers can produce components that are interchangeable, making it easier to repair or replace parts within a system. This standardization is especially helpful when dealing with international suppliers, as it guarantees that the fittings from different manufacturers will be compatible.

-

Durability and Strength: Metric hose fittings are engineered for durability and long-lasting performance. Materials like stainless steel and brass are commonly used due to their strength and ability to withstand harsh environments, including extreme temperatures and corrosive substances. The robust design of these fittings ensures that they can withstand not only high pressure but also environmental stresses, which is crucial in industries like oil and gas, automotive, and heavy machinery.

-

Flexibility in Application: Metric hose fittings are used in a wide range of applications, making them incredibly versatile. Whether you’re working on an automotive system, a construction machine, or a hydraulic circuit, these fittings are designed to handle various fluids and gases with different viscosity and pressure levels. The ability to use them in so many different environments makes them a go-to choice for many engineers and system designers.

-

Precise Fitment: Another important advantage of using metric hose fittings is their precision. Due to their metric sizing, these fittings provide a more accurate and secure fit compared to imperial fittings. This precision helps prevent common issues like fluid leakage or pressure drop, ensuring that the system operates as intended.

| Feature | Metric Hose Fittings | Imperial Hose Fittings |

|---|---|---|

| Measurement System | Millimeters (mm) | Inches |

| Standardization | ISO 8434-1 (DIN 2353) | SAE (Society of Automotive Engineers) |

| Common Materials | Stainless steel, brass, aluminum | Stainless steel, brass, copper |

| Thread Types | Metric threads, typically parallel or tapered | NPT (National Pipe Thread), BSPT |

| Applications | Automotive, industrial, hydraulic systems | Automotive, plumbing, construction |

Why They Matter in Fluid Systems

The performance of any fluid system largely depends on the quality of the hose fittings used. Substandard or poorly fitted hose components can lead to a range of problems, including fluid leaks, reduced efficiency, or even system failure. Given the critical role that fluid systems play in many industries—such as automotive, agriculture, and industrial machinery—the reliability of hose fittings becomes essential. The use of high-quality metric hose fittings guarantees that the system will operate smoothly and efficiently, even under demanding conditions.

In fluid systems, the main objective is to ensure a continuous, leak-free flow of fluids or gases from one point to another. Metric hose fittings provide this assurance by creating strong, precise connections that are designed to endure high pressures, vibrations, and varying temperatures. When you choose the right fittings, you not only enhance the efficiency of the system but also increase its safety and longevity.

Frequently Asked Questions (FAQ)

-

What is the difference between metric and imperial hose fittings?

Metric hose fittings are measured in millimeters and follow international standards like ISO 8434-1, while imperial fittings use inches and follow standards like SAE. Metric fittings provide more precision and are typically used in Europe and other metric-system-based countries. -

Can I use a metric hose fitting with an imperial hose?

While it’s possible to use a metric fitting with an imperial hose, it’s generally not recommended due to differences in sizing and thread types. For best results, always match the fittings with the appropriate hose type. -

What materials are metric hose fittings made from?

Metric hose fittings are typically made from durable materials like stainless steel, brass, or aluminum. These materials are chosen for their strength, corrosion resistance, and ability to withstand high pressures. -

How do I choose the right metric hose fitting?

To select the right metric hose fitting, consider the pressure rating, size, material compatibility, and thread type required for your specific application. Ensuring these factors match will help maintain system integrity and avoid issues like leaks or corrosion. -

What are the common applications for metric hose fittings?

Metric hose fittings are used across a wide range of industries, including automotive, construction, hydraulic systems, and machinery. They are ideal for connecting hoses to various equipment, ensuring efficient fluid or gas transfer.

References

- ISO 8434-1: “Metallic Tube Fittings - Part 1: 24° Conical Compression Fittings.”

- Swagelok. “Understanding the Importance of Tube Fittings.” Swagelok, 2020.

- Parker Hannifin. “The Role of Hose Fittings in Hydraulic Systems.” Parker Hannifin, 2018.

- Eaton Corporation. “Hydraulic Fitting Standards.” Eaton, 2021.